3D printing, also known as additive manufacturing (AM), has firmly established itself as a revolutionary force in modern manufacturing. This technology, which builds objects layer by layer from digital designs, offers a radical departure from traditional subtractive methods where the material is removed from a larger block to create parts. Today, 3D printing is making waves across industries—from automotive to aerospace and medicine—by providing cost efficiency, reducing waste, and unlocking unprecedented design possibilities. As demand grows, it promises not only innovation but also significant job creation and economic impact.

Manufacturing has traditionally relied on subtractive processes, where materials such as metal or plastic are carved or milled to create parts. This method often results in material waste and limited design flexibility. In contrast, additive manufacturing constructs parts layer by layer directly from a digital model. This revolutionary approach has already disrupted several industries by offering a more efficient, cost-effective, and sustainable alternative to conventional methods.

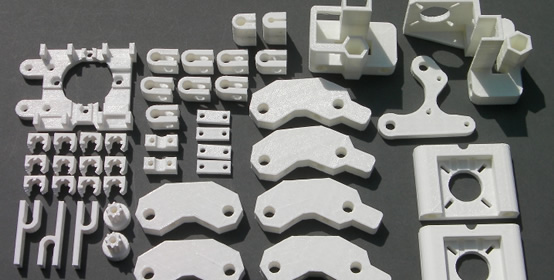

The range of materials available for 3D printing has expanded significantly, now including advanced thermoplastics, ceramics, high-performance polymers, metal powders, and even biocompatible materials. This diversity allows manufacturers to produce complex components that would have been impossible or prohibitively expensive to create using traditional methods. Hybrid manufacturing techniques, which combine additive and subtractive processes, are also emerging, enabling companies to optimize production with greater precision and less waste.

With these advancements, 3D printing is redefining the possibilities of what can be manufactured, opening up new opportunities in both existing and emerging sectors. As the technology evolves, its applications continue to broaden, driving demand across multiple industries.

The medical field is one of the most rapidly evolving sectors in 3D printing, with technology driving significant advances in areas such as prosthetics, surgical implants, dental devices, and anatomical models for surgical planning. Companies like Invisalign have leveraged 3D printing to produce millions of customized dental aligners, while others use it to create ceramic crowns, patient-specific implants, and even synthetic bones. These innovations are revolutionizing patient care through personalization, cost reduction, and speed.

3D printing is not just a tool for creating custom-fit devices; it is transforming the entire landscape of healthcare. Prosthetics, which have traditionally been expensive and time-consuming to produce, are now being customized at a fraction of the cost. This allows for quicker turnaround times and more affordable solutions, particularly in underserved regions. Beyond prosthetics, 3D printing is enabling the production of highly complex surgical instruments and implants that conform precisely to a patient's anatomy, reducing surgery time and improving outcomes.

Another significant area of application is in anatomical modeling. Surgeons can now use 3D-printed models based on patient scans to better plan and practice complex surgeries, leading to improved precision and patient outcomes. These models can also serve as educational tools for medical students and professionals.

Looking ahead, the potential for bioprinting is one of the most exciting prospects in medical 3D printing. Researchers are currently exploring the use of bio-inks—combinations of cells, growth factors, and biomaterials—to fabricate tissue-like structures that mimic natural human tissue. Recent advancements have led to breakthroughs in bio-printed skin, which is used to treat burn victims, and in the development of customized tracheal splints and artificial blood vessels. These advancements are paving the way for even more complex applications, such as bio-printed organs for transplantation.

In the future, bioprinting could enable the creation of fully functional organs like kidneys, livers, and hearts using a patient’s own stem cells. This could revolutionize organ transplantation, significantly reducing the risk of rejection and the need for immunosuppressive drugs. Additionally, advancements in biocompatible and biodegradable materials could lead to the development of temporary implants that support tissue regeneration, further expanding the scope of 3D printing in medicine.

The aerospace industry has rapidly adopted 3D printing, driven by the need for lightweight, high-performance parts that can withstand extreme conditions. One of the most transformative applications of 3D printing in this field is the production of complex components that were previously impossible or too costly to manufacture through traditional methods. GE Aviation, for instance, has successfully used 3D printing to manufacture fuel nozzles that are 25% lighter and five times more durable than those produced using conventional methods. These nozzles, which were once composed of 18 separate parts, are now manufactured as a single, unified piece, reducing assembly time and costs.

3D printing also allows for rapid prototyping, enabling engineers to quickly produce and test multiple iterations of a design without incurring high costs. Aurora Flight Sciences, a leading aerospace innovator, recently demonstrated an unmanned aerial vehicle with 3D-printed parts that achieved speeds of up to 150 mph while weighing only 33 pounds. This capability illustrates the potential of 3D printing to create lightweight yet durable components, which are crucial for both aviation and space exploration.

Looking forward, the potential applications of 3D printing in space are vast. NASA and other space agencies are exploring the use of 3D printing to create parts directly in space, reducing the need for large inventories and costly resupply missions. The technology could be used to print everything from rocket components to entire habitats on Mars, addressing challenges like weight constraints and logistics. However, significant challenges remain, such as the need to standardize materials and ensure quality control, particularly in the harsh conditions of space.

The automotive industry is another sector that is leveraging 3D printing to drive innovation. This technology offers numerous benefits, including reducing vehicle weight to enhance fuel efficiency and performance, accelerating the prototyping of new parts, and enabling highly customized designs. Local Motors, for example, unveiled the Strati, the world’s first 3D-printed car, which took only 44 hours to produce. The company plans to reduce production time for its next model to just 12 hours, demonstrating the potential for rapid, on-demand manufacturing.

3D printing is enabling the creation of lighter, more energy-efficient components and supports the design of advanced systems for electric vehicles (EVs) and autonomous cars. With 3D printing, manufacturers can quickly iterate designs, reduce costs, and eliminate the need for expensive tooling and molds. The technology is also being used to develop innovative solutions for electric powertrains, battery housings, and sensor enclosures, all of which are critical to the future of EVs.

Beyond speed and cost efficiency, 3D printing supports sustainable manufacturing practices by minimizing material waste and reducing carbon footprints. Decentralized manufacturing, where parts are printed on demand near the point of use, is becoming a reality. This approach reduces shipping costs, shortens supply chains, and decreases environmental impact, aligning with global sustainability goals.

The global market for 3D printing is expanding rapidly, with projections estimating it will exceed $50 billion by 2030. This growth is driven by increased adoption across various industries, ongoing technological advancements, and the development of new materials that lower costs and enhance performance. Major players such as HP, Stratasys, and 3D Systems are continuously innovating, pushing the boundaries of what is possible with additive manufacturing.

The economic impact of 3D printing extends beyond manufacturing. As more businesses adopt this technology, it is expected to create new jobs in areas like design, engineering, software development, and materials science. Additionally, the demand for skilled workers trained in 3D printing is prompting the development of new training programs and educational initiatives. The ability to produce goods locally may also reduce reliance on overseas manufacturing, reshaping global supply chains.

Contrary to fears that automation will lead to job losses, the growth of 3D printing is expected to create a wide range of new job opportunities. The demand for skilled workers will increase in fields like machine operation, digital design, engineering, maintenance, and quality control. As companies invest in this technology, they will need employees who understand its intricacies and can integrate it into existing workflows.

Educational institutions and companies are already stepping up to meet this demand by offering specialized courses and training programs to prepare workers for the future. Reskilling and upskilling will be critical as 3D printing becomes more mainstream, requiring workers to learn new skills related to digital design, 3D modeling, and additive manufacturing processes.

While the benefits of 3D printing are clear, several barriers remain to its widespread adoption. Some companies still perceive the technology as expensive or unproven, while others are concerned about the quality and durability of 3D-printed parts. However, these challenges are gradually being addressed through continuous advancements in material quality, printer speed, and post-processing techniques.

As costs continue to decrease and the range of printable materials expands, 3D printing is becoming more accessible to businesses of all sizes. Software solutions that optimize design for additive manufacturing are helping to further reduce costs and improve performance, driving broader adoption across industries.

As the technology matures, new opportunities for 3D printing are emerging in sectors such as construction, where it is being used to build homes and infrastructure more quickly and sustainably. In food manufacturing, 3D printers are creating customized meals, while in fashion, designers are using the technology to produce custom clothing and accessories.

3D printing is also contributing to the circular economy by enabling more sustainable production practices. By reducing material waste, energy consumption, and carbon emissions, additive manufacturing is proving to be a valuable tool in the fight against climate change, allowing businesses to achieve sustainability goals while remaining competitive.

3D printing is reshaping industries, creating new possibilities, and driving economic growth. From medical breakthroughs to aerospace advancements, and from automotive innovation to new job opportunities, 3D printing is at the forefront of a manufacturing revolution. As technology continues to evolve, its applications will expand further, opening up new frontiers in design, production, and sustainability. For businesses, embracing this technology now is not just an option; it is a strategic imperative.

For those interested in the future of manufacturing, exploring 3D printing is essential. Whether you're a designer, engineer, manufacturer, or entrepreneur, understanding and leveraging the power of additive manufacturing could be your key to staying ahead in an ever-changing world. Dive into the latest trends, invest in training, or consider how AM can enhance your business processes. The possibilities are virtually limitless, and the future is being printed—one layer at a time.