Space travel has been a daunting task ever since its inception. Using rockets to send cargo—human or otherwise—into space is labor intensive, expensive, and wasteful. Now, new aerospace startups are challenging the way we think about rockets. With 3D-printed reusable rocket technology, space travel can be cheaper, easier, and more sustainable.

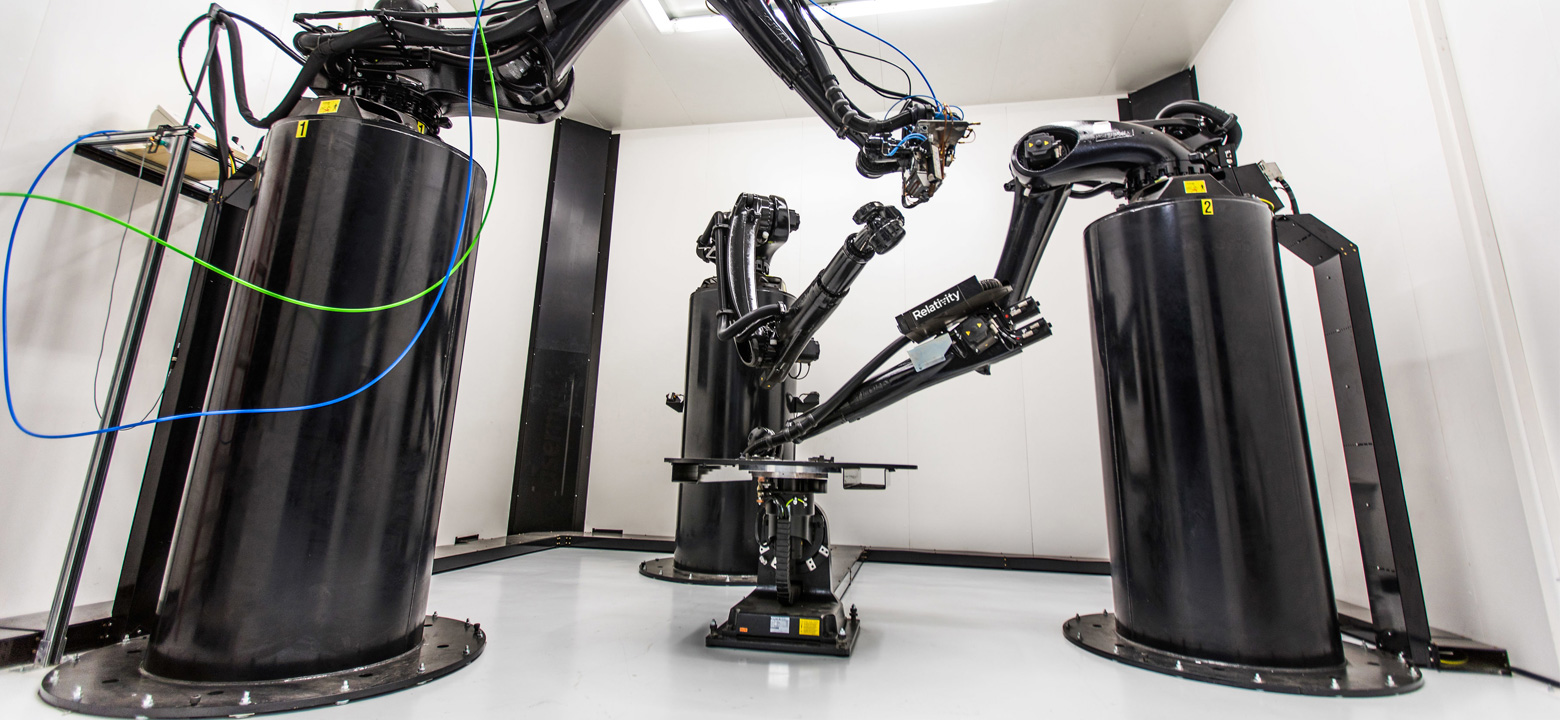

At only five years old, Relativity Space Inc. is a pretty young aerospace startup. Founded by Jordan Noone and Tim Ellis, their vision is to simplify rocket construction by using gigantic 3D printers. After reaching a $2.3 billion valuation, hiring 230 employees, and forming a 120,000 square foot manufacturing facility located in Long Beach, the company has already created a prototype of their Aeon 1 rocket engine.

Meanwhile, in New Zealand, the space startup Rocket Lab is successfully working toward a reusable rocket. Earlier in 2020, the company was selected by NASA for their Pathfinder Mission to the Moon. Afterward, Rocket Lab acquired Sinclair Interplanetary, and used its Electron space vehicle to deploy 30 small satellites. They managed to recover the rocket's first stage, which is a great leap toward fully reusable rockets. The Electron also has the distinction of being the first battery-powered rocket with a 3D-printed engine.

When Rocket Lab recovered the Electron rocket's first stage, it went like this: After launch, at an altitude of about 80km, the Electron's first and second stages separated as intended. Immediately afterward, control systems oriented the first stage in the proper angle for safe re-entry. A small parachute helped to slow and stabilize the first stage as it returned to Earth, while a larger one further slowed it for the last leg of the fall. After it splashed down, Rocket Lab's recovery team retrieved it for further examination.

Of course, 3D printing an entire rocket is a bit different from 3D printing an engine. That's where Relativity comes in. Most of their efforts thus far have been geared toward creating the kind of 3D equipment needed to take on a task like that. Now, they need to determine how to simplify and streamline rocket manufacturing to use the lowest number of individual parts possible. With that achieved, something akin to Rocket Lab's recovery process could result in a reusable, completely 3D printed rocket.

While additive manufacturing is a pretty expensive way to produce metal parts, 3D printing a rocket would be cheaper than conventionally building one. The secret lies in two things: consolidation, and software.

Consolidating a rocket's parts leads to fewer individual parts, and a simpler design. 3D printing allows manufacturers to make unconventional parts that would be difficult, if not impossible, to produce by other means, but use as little material as possible. While the individual parts themselves is fairly expensive, the stripped-down, streamlined design of a 3D printed rocket makes it less expensive.

Software helps the economics by allowing for on-the-fly adjustments and tweaks. Unlike manufacturing methods that require re-configuring entire assembly lines every time a change needs to be made, additive manufacturing is much simpler. This would let manufacturers handle any workarounds they need to, at relatively little expense.

Reusable rockets would also be more sustainable than conventional ones. While conventional ones are effectively trashed after use, reusables aren't. This reduces the amount of raw material that space travel requires, lessening its environmental impact and further reducing costs. If the rockets are battery-powered and that power can be produced by a renewable means, that further contributes to their sustainability compared to models that use traditional fuel.

Rocket Lab's next mission is to analyze the data from the Electron's first stage. After that, they will attempt a mid-air retrieval using a helicopter. This would theoretically reduce the amount of damage the rocket would sustain by splashing down or landing on dry land, contributing to its reusability and extending its working life. After retrieval, they will refurbish the rocket and prepare it for re-launch.

Relativity's next step is to attempt a test flight of its Terran 1 rocket in 2021. If it proves to be a viable launch vehicle, the company hopes to begin commercial launches in 2022.

Space travel is expensive, and missions are often constrained by the high cost of transporting necessary cargo and personnel. 3D printed, reusable rockets present a way to dramatically lower the cost of launches, as well as reduce their environmental impact. While the technology still has a few steps before it can be fully implemented, the progress shown by Relativity and Rocket Lab is extremely promising. Following Rocket Lab's helicopter-assisted rocket retrieval, refurbishment, and relaunch, and Relativity's 2021 test flight, we could be seeing fully 3D printed, reusable rockets within the next few years.