The pandemic has caused shortages in goods across virtually every industry. Grocery stores saw shortages in meat and toilet paper, hospitals were short on needed medical supplies, and even coins fell short when lockdowns interrupted their circulation. There's one shortage, in particular, that's threatening to bring manufacturing to a grinding halt: microchips.

Unlike shortages of personal protective equipment and medical personnel, the microchip shortage wasn't a direct consequence of the novel coronavirus. Instead, a combination of factory closures and shifts in demand caused stocks of microchips to plunge.

With schools closed and millions of people working from home, electronics sales surged. Individuals had to outfit new home offices and set up remote schooling stations, while schools and workplaces had to set up or bolster their remote working capacity.

While electronics sales soared, automotive sales dropped. With nobody able to go anywhere, the automotive industry wasn't moving many new vehicles. The automotive industry is a major consumer of microchips. When their orders for new vehicles fell, chip manufacturers shifted to producing microchips for consumer electronics and other components instead. When the automotive industry rebounded sooner than expected, it was a mixed blessing. Demand increased, but there aren't enough microchips to fill it.

In the midst of all of this came the somewhat ill-timed rollout of 5G technology. Adding new infrastructure created even more demand for microchips. On top of this, Chinese technology company Huawei placed a large order in order to bolster their stockpile of microchips.

Part of the problem is that the US doesn't produce many microchips domestically. The vast majority—over 80% of processor chips—are manufactured in Taiwan and South Korea. This lack of domestic production makes US-based manufacturers particularly vulnerable to supply chain disruptions. One of the best ways to avoid supply chain issues during a crisis is a combination of local and backup suppliers, two things that the US currently lacks.

It would be easier to list the industries that aren't affected by the shortage. Everything from our phones, to cars, to luxury handbags use microchips for various purposes. Right now, the consumer electronics and automotive industries are the most severely impacted.

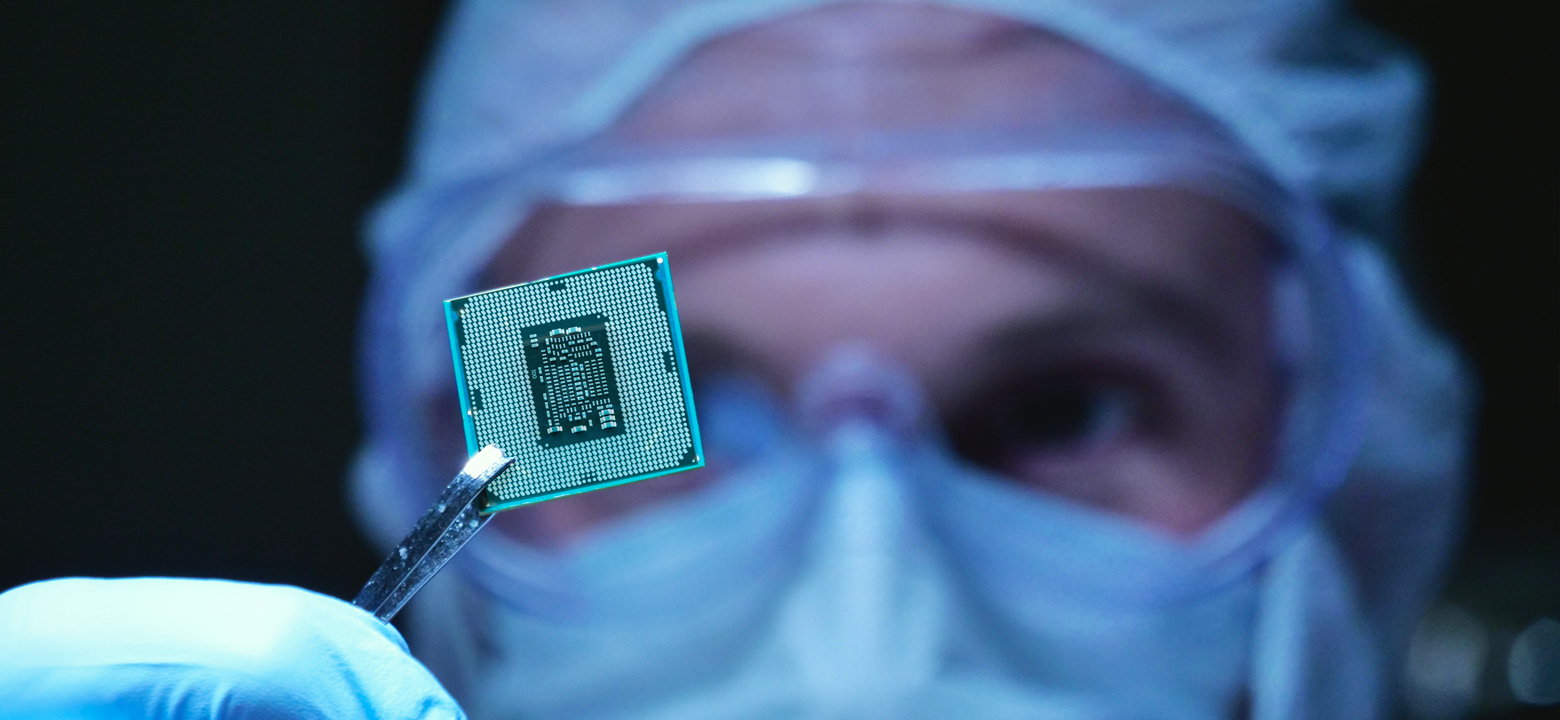

Microchips rely on thin wafers of silicon. These wafers come in different sizes, depending on the kind of chips being produced by the factory—larger wafers allow factories to produce more chips at one time. for years, the 200mm (or 8”) wafer has been the most common, and production methods have been optimized for this size. These wafers are supposed to be supplanted by larger, 300mm wafers. New electronics are switching to these larger wafers, but many devices—and cars—still use the older, 200mm size. This popularity, coupled with shifts in demand, has created problems with sourcing chips produced on 200mm wafers. As a result, any industry that relies on wafers of this size is feeling the pinch.

Manufacturers responded to the shortage by increasing their production capacity, but this isn't an immediate fix. It takes roughly a year and a half to two years for a new manufacturing plant to become fully operational, and more time to fine-tune operations and reach optimum production yield.

Some experts anticipate the shortage lasting until July, at the earliest. Others expect it to go much longer, with some chips remaining in short supply until 2022. At the moment, if an automotive manufacturer were to place an order for microchips, it would take until next January to fill it.

In the interim, consumers may face long wait times to buy new automotive models. Consumer electronics, especially those from smaller companies, maybe more expensive and difficult to find. Larger companies, which have the buying power to maintain a stockpile of chips, will be buffered against the worst of the shortage for awhile.

Advances in technology come with advantages and disadvantages. In this case, the ubiquity of microchips means that the effects of a shortage are far-reaching. While the pandemic was ultimately the trigger, a variety of factors—from the environmental to the economic, to the geo-political—have contributed to the situation.